Advances in extraction, smelting, and fabrication technologies are resulting in steel framed housing becoming an increasingly viable alternative to traditional timber framing for housing (currently, timber is the product leader in the Australian residential building market).

The domestic (Australian) and global timber shortages are resulting in loyal timber builders to begin assessing alternative products, with many developers making the switch to cold rolled steel or in Australia Cold Formed Steel (CFS) or other colloquially known as “Light Gauge Steel” (LGS) – the terms are essentially interchangeble and represent “Cold Rolled Steel”.

Steel has a number of unique advantages which are ideal for the harsh Australian environment, such as producing less wastage than timber, as well as being more durable with higher resistance to fire and pest damage (e.g. termites).

To understand why Cold Rolled Steel is so “hot” at the moment, we have written this article to take a deeper look at the difference between hot and cold rolled steel.

Hot Rolled Steel

Hot rolling is a mill process which involves rolling the steel at a high temperature (typically at a temperature over 900° C), which is above the steel’s recrystallisation temperature. When steel is above the recrystallisation temperature, it can be shaped and formed easily, and the steel can be made in much larger sizes.

Hot Rolled Steel is typically cheaper than Cold Rolled Steel since it is often manufactured without any delays in the process, and therefore the reheating of the steel is not required (as it is with cold rolled). When the steel cools off it shrinks slightly thus giving less control over the size and shape of the finished product when compared to Cold Rolled Steel.

Cold Rolled Steel

Cold Rolled Steel is essentially Hot Rolled Steel that has had further processing. The steel is processed further in cold reduction mills, where the material is cooled (at room temperature) followed by annealing and/or tempers rolling. This process produces steel with closer dimensional tolerances and a wider range of surface finishes.

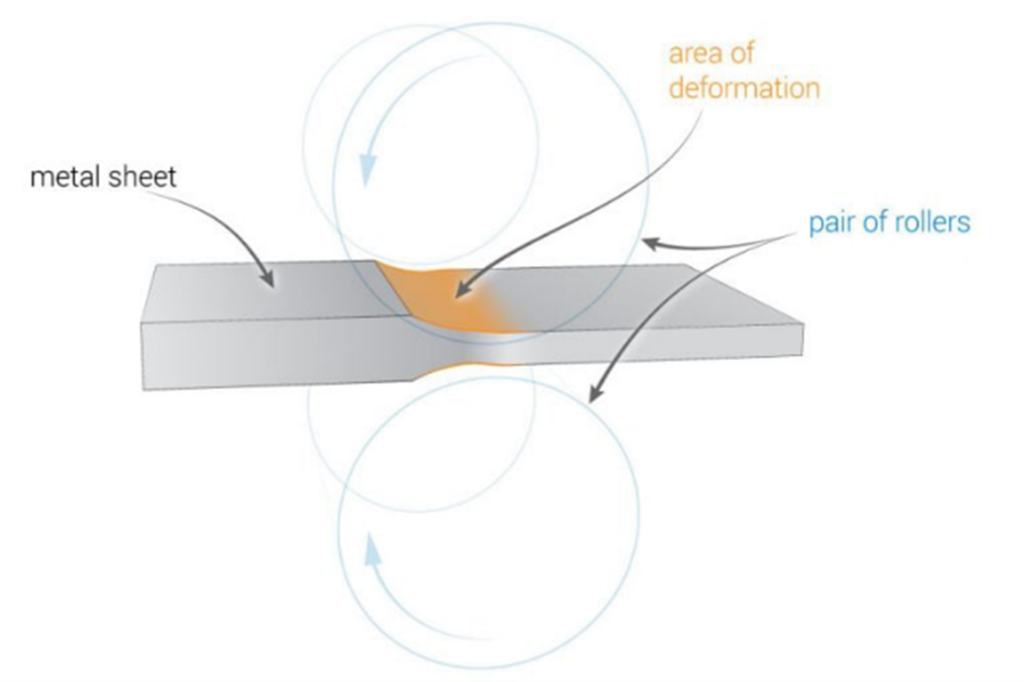

The term “cold rolled” is often mistakenly used on all products, when the product name refers to the rolling of flat rolled sheet and coil products. An example of the rolling process is shown in Figure 1 for reference.

Figure 1: Process of cold rolling steel (MatMatch 2022)

In summary, cold rolling is an industrial process that is used to change the material properties of steel that start off as sheets or strips of metal and once rolled, are turned into rolls of steel coil. Rolling is an important function of the steel industry. The steel fabrication process involves passing the metal through a pair of rollers.

There are two main types of rolling processes:

- Flat rolling – where the finished product is a sheet of steel; and

- Profile rolling – where the finished product is a bar or rod of steel.

Why Roll Cold?

Cold Rolled Steel is typically harder and stronger than standard Hot Rolled Steel. Cold Rolled Steel has increased resistance against tension breaking at lower temperatures as well as against deformation and damage hardening processes.

Cold Rolled Steel is also highly versatile, and due to its strength and low weight can be a better material to use for a much broader range of architectural building design.

Steel versus Timber Frames

A brief comparison of the benefits and disadvantages of building houses with Cold Rolled Steel, instead of traditional timber includes:

Benefits:

- Termites cannot eat steel – Many timber-framed homes suffer termite damage which is often not covered by insurance (noting that repairs can cost well into the thousands);

- Fire Resistance – Steel is non-combustible and retains its shape at much higher temperatures than timber and is therefore more fire resistant;

- The steel is 100% recyclable and therefore has environmental benefits (plus you do not need to contribute to deforestation);

- Off-site Construction – Steel frames can be fabricated and transported to site in the factory resulting in more rapid construction; and

- Steel Framing can be very light, as Cold Rolled Steel is very strong.

Disadvantages:

- Steel is often more expensive for the raw material compared to timber as the cost of its raw material has more associated value, however this is offset by the lower lifecycle costs compared to timber framing (based on the risk of termites etc.);

- Steel is also more labour intensive, and consequently carpenters and other trades can cost more to work around steel when compared to timber, however this is likely to change with the growing demand and continued use of the material as tradesmen become more skilled at using the cold formed steel materials;

- The high amounts of energy required in the initial steel rolling / production has environmental impacts, however it is noted that it does not involve felling forests or tree plantations; and

- The use of steel frames can result in corrosion due to a combination of wetting and drying which can negatively impact the steel framing (however, this risk can easily be designed out!).

An example of how the frame sits behind (and supports) exterior building cladding is shown in Figure 2 for reference.

Figure 2: Internal framing of a CFS / LGS framed house (Architecture & Design 2022)

Whatever material you choose to build with, JJ Ryan Consulting’s Structures team has significant expertise with both timber and steel frames and can help to ensure your next building will stand the test of time.

For more information, contact us today at enquires@jjryan.com.au to understand more about the range of services our team provide.

References utilised and further reading can be found here:

MatMatch (2022): https://matmatch.com/learn/process/cold-rolling

Architect & Design (2022): https://www.architectureanddesign.com.au/features/list/steel-framed-homes-timber-vs-steel-frame-pros-cons